So, I am kind of embarrassed to even mention this. But, maybe some of you out there ran into the same trouble as me. If you look at the picture above you can see a gap between the bottom of the thread cone and the thread holder plate. The thread cone is sitting nicely on top of the thread holder - the only problem with this scenario is that the thread slips down and gets caught underneath as I quilt. It is totally frustrating to be quilting and have to stop because the thread gets caught, creating terrible tension problems. Not to mention a million times walking to the other side of the machine and around the table to fix it.

I was so frustrated when this was happening to me. I first tried turning off my ceiling fans to help so the thread isn't moving - that helped a little, but then with a stroke of luck I figured out the problem.....

PUSH THE CONE DOWN Dummy!! Not you - me. Seriously. So simple, yet so hard at the same time. Now, in my defense, I can only do this because the hole in the Fil-Tec Glide thread is large enough to fit over the top and bottom of the thread holder. I just didn't realize it because I have used So Fine for a lot of my projects and the hole is not big enough to fit over the whole thread holder, it just sits nicely on top.

PS - I am using Glide in the top and So Fine for the bobbin on my current quilt. I love both threads ;-)

Okay, so now that I completely embarrassed myself I have to tell you about a different scenario that was a huge blessing in disguise. I was working on a quilt yesterday and I kept thinking that I need to oil and re-distribute the grease on my gears for my machine. When I went to grease the gears, out came the above screw attached to my grease ridden finger. I panicked because I hadn't seen this before - I gave a quick call to my dealer Jen and she told me how to put it back in the right spot.

So, long story short - it could have been a terrible problem if I continued to quilt without this screw in place. Especially with a customer quilt on. Let's just say I am just so grateful to have caught this in time. Seriously. So grateful.

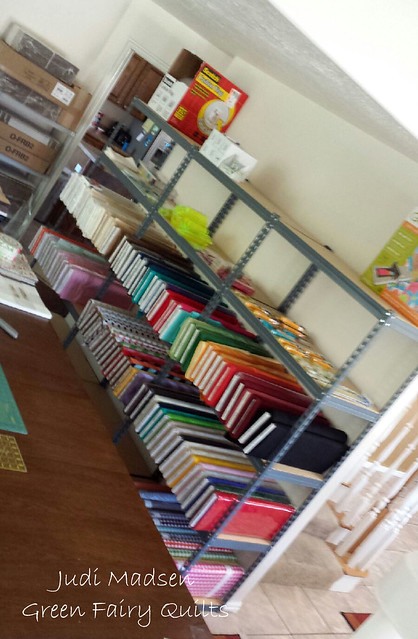

Now there are new things happening around here. We bought new shelves to hold our newly added fabric yardage. Clint and I are slowly expanding to carry more yardage and notions on our website, so be sure to check that out here.

I am also forcing my home improvement projects on everyone I love. Clint is thrilled to be helping with my gallery wall. He's a good poser too. ;-)

My sister Amy is here helping me with my studio. See the green? I am beyond excited. I will be sure to share with you the finished project as soon as I am done. I don't think I have even shown you my whole room and we have been here for over six months now. Wow, time flies.

20 comments:

It's amazing how the smallest thing can make such a big difference with our machines. I was using a much finer thread than I normally use and had to put the tension on my bobbing case way down. The screw on the arm fell out, not the tension screw on the case but on the arm. It was the tiniest screw I couldn't even see it. Lets just say I eventually figured out what the problem was but not before a few tears.

I LOVE Glide thread - use it almost exclusively - but it's very slick - and it will fall under the cone if you don't do something to stop it - I use the little net socks - put one on the cone as I'm loading it - haven't had that problem any more and it also just helps to keep the thread tension good as it's being pulled thru the machine.

Oh dear, isn't it great you can laugh at yourself! Don't we all have moments like that? I sure do!I laugh at myself lots!!

I see you have a saddle seat in your studio, aren't they great.

I do like Nikki does when I use Glide - use that netting sock so it guides the thread upward where it belongs! Love your green room - you'll feel great when everything is put together.

sometime I have to put a smaller cone up in the bottom of the larger cone so it wont rattle around

diana

I just figured out the automatic button hole maker on my machine and I'm over the moon! It's the little things that excite of sewing women. You do such beautiful work, I'm always inspired when I visit your blog.

I love the combo of Glide and SoFine. I put a piece of cut off panty hose over my cone, that works better for me than the thread nets.

I am a netting sock girl, also! Love your creative juices and your humility.

You're making terrific progress on your lovely home, Judi. So happy for you! And I loved that you shared your "ah-ha!" moment with everyone. We all have them. You just had the guts to share it! I wonder how many people will read your blog post and think, "wow, all I need to do is push that cone down"?

Wow, I'm glad I read the comments - just started using Glide thread and I love it, but it is so-o-o-o slippery! I'll have to give the nets a try. PS Here's my aha moment - you know how thread cones have that lovely plastic wrap on top of it? Well, I used to pick a spot in it and peel it off. My niece came in one day, picked up a cone, and just lifted the plastic cover, whole, up from the top. Aha! Boy did I feel dumb!

I started using Glide after you mentioned it in a post (I don't have a longarm, but I still like it). Right now Fil-Tec has an awesome deal where you can get 48 spools for like $80 - I ordered it yesterday.

I was just looking at Superior's Sew Fine this morning- what is the difference between that and Glide?

Thanks for the studio up-date! The tips and tricks are great especially for this newbie!

Thanks for the studio up-date! The tips and tricks are great especially for this newbie!

Nope, I've decided nothing is dumb. I, too, have had silly things like that happen with my longarm. Just last night I had to do some ripping (sigh), and I was under the table and my hubs says, why don't you just roll it back on the roller here and you can work on top of your table. OK, see, we all do silly things. Thank goodness we figure them out!!

You are a hoot. Glad someone else does things the hard way before you get that lightbulb moment. Dah! As I say to myself. Where was my brain. Sheesh. I use glide thread often and I had that puddling effect. I solved it by putting a small piece of batting in between the thread and the threader (my own technical term, you know that thingy just above your spool of thread) and that kept enough tension to keep my thread from puddling.

I have been using filtec bobbins for a few months and just love them. I have purchased a few spools as well but have a really hard time getting them to run through without a lot of breakage. I have noticed when working on the front of the machine that it alomost looks like it is unraveling after it passes from the needle arm to the needle. Have you noticed this and if so,how can I eliminate that?

Where did you get that saddle stool we can see in the photo of your sister Amy in your studio?!? I need one!

A green room for Green Fairy Quilts? Sounds like it was meant to be!! :-)

Scary story finding that screw! I have an A-1 as well...hope I never find one :-) Randi at A-1 just helped me changed out some sensors. what a relief to get my machine sewing again!

As to the thread falling, I use a piece of old nylon stocking...it fits over the thread like one of the nets but the thread doesn't get caught at the top.

Love watching your quilting ideas!

Post a Comment